7 October 2014

First coat of paint on the patched deck

I am very pleased with the outcome of the deck repair. The first coat of paint is on and the repair is undetectable to touch. Still shows through visually, and it needs probably two more coats, but then it should be undetectable at all.

30 September 2014

Repairs and changes ongoing.

The basic repair to the cockpit deck is complete. I stuck in the infill panel with epoxy and then planed the patch down to flush with the deck. Some bits were a bit too low, so I spread on a layer of epoxy thickened with micro-balloons, which is supposed to give an easily sanded finish. I tried the technique of putting on the first layer with a notched spreader. The ridges are sanded down and then the remaining grooves filled in. It seemed incredibly hard, so I ended up planing off the ridges.

I then filled in the grooves with ordinary marine filler. This did sand down easily and although it looks a mess, it is completely smooth. When it is painted I have hopes that it really will be undetectable.

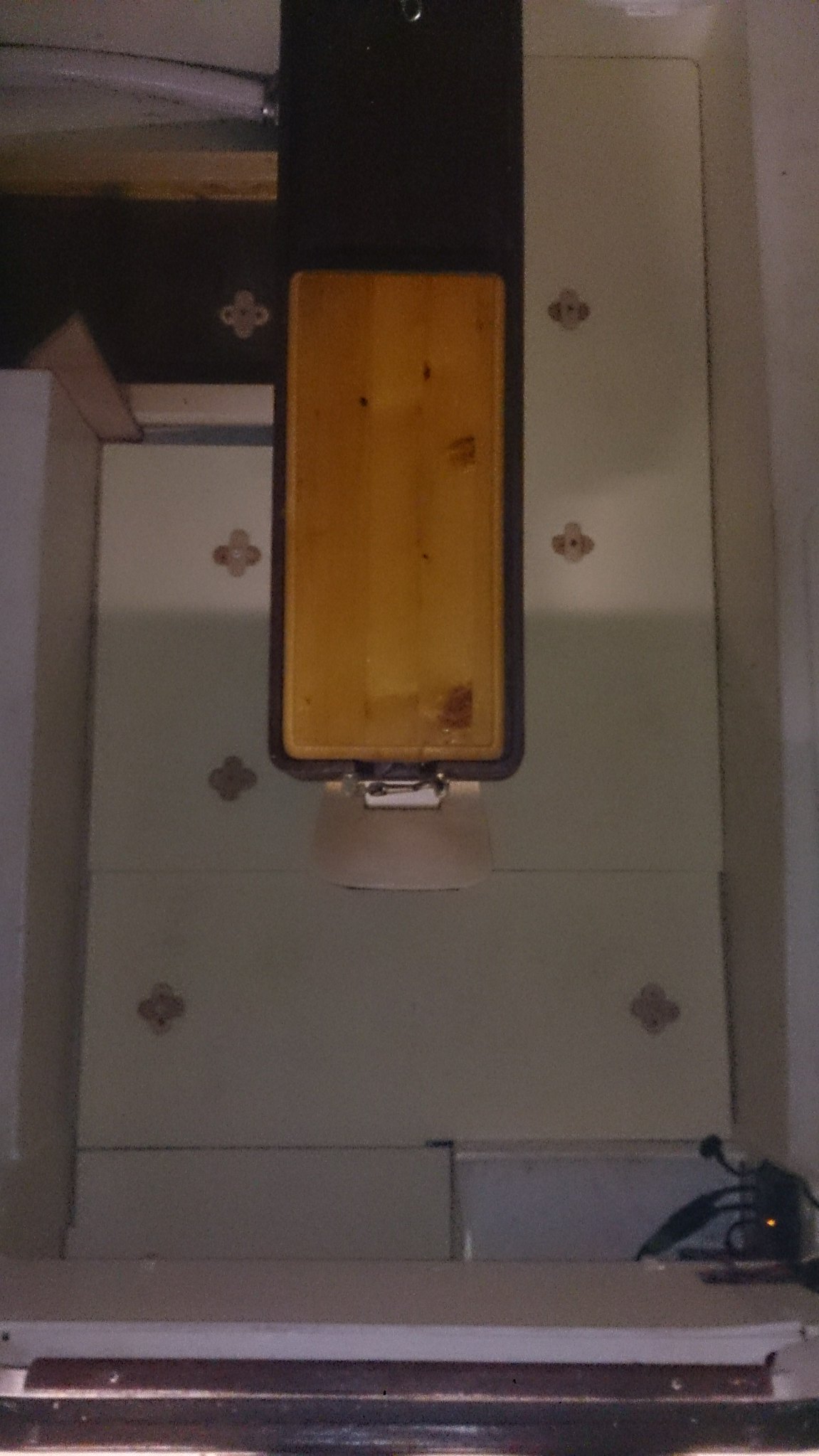

I have fitted turn buttons to the cabin floors and painted the boards with non-slip paint. I should now be able to lift the floor quickly at any time. I am not convinced by the paint as I think it may hold too much dirt, but I want to do away with the weight of floor finishes. I add too much to the boat and want to cut back next year.

I then filled in the grooves with ordinary marine filler. This did sand down easily and although it looks a mess, it is completely smooth. When it is painted I have hopes that it really will be undetectable.

I have fitted turn buttons to the cabin floors and painted the boards with non-slip paint. I should now be able to lift the floor quickly at any time. I am not convinced by the paint as I think it may hold too much dirt, but I want to do away with the weight of floor finishes. I add too much to the boat and want to cut back next year.

21 September 2014

Fitting deck glands

I came back form the Southampton Boat Show with bags of bits. One has proved far better than I anticipated. I wanted to fit a deck gland round the fuel pipe, so that I could block off the existing opening into the locker. This has let a lot of water in in the past, especially when I have several people on board and the stern is depressed. I assumed I would have to drill a new hole for the fuel pipe, and fill in the existing large hole. What I found was that the gland base covers the existing hole perfectly, so I can carry on using the same hole, but now it is waterproof. Not often that things just fit so neatly.

I am going to reroute the depth sounder cable to the opposite side of the boat. I can take it directly into the end of the quarter berth, through another deck gland, and then through trunking to the display unit. This means no unsealed holes into the cabin, which is how it is routed at present.

I am going to reroute the depth sounder cable to the opposite side of the boat. I can take it directly into the end of the quarter berth, through another deck gland, and then through trunking to the display unit. This means no unsealed holes into the cabin, which is how it is routed at present.

18 September 2014

Re-doing deck repair

I am re-doing the repair to the deck in the cockpit. It didn't look good and still flexed too much. When I had a closer look, the crack went right to the edge of the hatch opening. So I cut out a much larger area and started gluing substantial 12mm plywood beams under the edges. The deck around the hatch is very solid now, and when the infill goes in, it should be far better. Looks terrible at the moment.

16 September 2014

Outboard well blanking plate.

The blanking plate works well, and with four crew on board it is essential to fit it. Otherwise far too much water sloshes up into the cockpit and the self bailers in the sumps can't empty it quickly enough. Fitting the plate under way was very difficult. The space under the outboard is cramped and awkward to get at. The force of up welling water pushes the board out of the way until you can finally twist the locking bar in place. I have modified the set up.

First, I have enlarged the lips at front and back of the well to support the plate. and screwed on intermediate one just aft of the outboard leg in the down position. All in epoxy coated 6mm marine ply. These will need to be anti-fouled.

Then I sawed the plate into two parts, with a bevelled cut, so the edge of the smaller part can rest on the larger. The large part will be put in as before, and can be used when the outboard leg is down, which will be a bonus. It can also be fitted from either side. Full length it can only be fitted under the raised engine from the starboard side.

The short forward length will be hinged to the side of the opening with nylon hinges, so it can be flapped down when needed.

The forward part will be under water all the time as it is permanently in the well. I have considered various ways of hinging the larger part, but there just isn't room under the engine to do it in a simple to use way. But it will be much easier to fit in the shorter length. The small part will be held down with its own oak turn-buckle.

First, I have enlarged the lips at front and back of the well to support the plate. and screwed on intermediate one just aft of the outboard leg in the down position. All in epoxy coated 6mm marine ply. These will need to be anti-fouled.

Then I sawed the plate into two parts, with a bevelled cut, so the edge of the smaller part can rest on the larger. The large part will be put in as before, and can be used when the outboard leg is down, which will be a bonus. It can also be fitted from either side. Full length it can only be fitted under the raised engine from the starboard side.

The short forward length will be hinged to the side of the opening with nylon hinges, so it can be flapped down when needed.

The forward part will be under water all the time as it is permanently in the well. I have considered various ways of hinging the larger part, but there just isn't room under the engine to do it in a simple to use way. But it will be much easier to fit in the shorter length. The small part will be held down with its own oak turn-buckle.

Subscribe to:

Posts (Atom)