I am going to continue this blog on a new Wordpress site. I have got tired of the restrictions and changes that occur to the image library here on Blogspot. Google try to tie the whole thing too tightly to Google+ and I have just got fed up with it. The old posts will stay here, but if you want to read any new ones, Please hop over to:

14 November 2014

2 November 2014

Oars finished, just have to try them out now...

I've applied about 5 coats of linseed oil to the oars, and will probably put on many more. That s the beauty of oil.

Bought two off-cuts of leather from ebay. I think they are left over upholstery bits. I also found an excellent articles on Paul Gartside's website on how to stitch oar leathers on, Very detailed and I would have made a real mess if I hadn't read it first. http://www.gartsideboats.com/faq/oar-leathers.html

Cutting the leather is slightly tricky, but it stretched nicely to fit. I didn't wet it as it was very soft already. Each leather needed about 50 holes punched on each long edge. These need to be done fairly carefully so that they match.

Stitching is with waxed whipping twine and two sail makers needles. I was worried the threads would pull right through the leather, but that never happened.

The oars fit in the boat nicely and I have made an arrangement of loops and bungies that I hope will hold them in place when towing

Bought two off-cuts of leather from ebay. I think they are left over upholstery bits. I also found an excellent articles on Paul Gartside's website on how to stitch oar leathers on, Very detailed and I would have made a real mess if I hadn't read it first. http://www.gartsideboats.com/faq/oar-leathers.html

Cutting the leather is slightly tricky, but it stretched nicely to fit. I didn't wet it as it was very soft already. Each leather needed about 50 holes punched on each long edge. These need to be done fairly carefully so that they match.

Stitching is with waxed whipping twine and two sail makers needles. I was worried the threads would pull right through the leather, but that never happened.

The oars fit in the boat nicely and I have made an arrangement of loops and bungies that I hope will hold them in place when towing

20 October 2014

Both oars largely complete

I have carved out the second oar, and again, am very pleased with the result. The weights of the two are within 20gms at about 1900gm each. They balance at almost the same point and they even fit the rowlocks, which was a bit of luck because I had forgotten to check those when I started!

Planing them to match was much easier than I expected. By laying the finished one alongside the one I was working on, I could continuously compare them visually, and using a cheap vernier calliper, I just compared thicknesses at any position along them. I still haven't managed to hollow out the blades either side of the central ridge. I bought a convex base spokeshave and it is one of the worse tools I have wasted money on. The curve of the blade doesn't match the curve of the base. The chip breaker doesn't fit properly, even after regrinding, and the blade was blunt. I couldn't get a single decent shaving off with it. I am planning to get some coarse sandpaper and a large diameter dowel, and have a go with that, but they will work as they stand. I still need to get some leather for each.

Planing them to match was much easier than I expected. By laying the finished one alongside the one I was working on, I could continuously compare them visually, and using a cheap vernier calliper, I just compared thicknesses at any position along them. I still haven't managed to hollow out the blades either side of the central ridge. I bought a convex base spokeshave and it is one of the worse tools I have wasted money on. The curve of the blade doesn't match the curve of the base. The chip breaker doesn't fit properly, even after regrinding, and the blade was blunt. I couldn't get a single decent shaving off with it. I am planning to get some coarse sandpaper and a large diameter dowel, and have a go with that, but they will work as they stand. I still need to get some leather for each.

12 October 2014

First oar largely finished and second under way

The first of my "Pete Culler" oars is largely finished, apart from a lot of sanding and maybe a little trimming here and there. Very satisfying thing to make. Lots and lots of planing of wood shavings, which has an almost zen like feeling to it. Hard to stop.

The handle was relatively easy to form, as it starts square, then circular. After that it tapers all the way to the tip, which is tricky. The blade has to be judged by eye and touch, it is very hard to measure anything. I couldn't hollow each side of the blade as I don't have a round bottomed plane, but I think it looks quite good without the hollow.

The really tricky part will be making a second oar to match.

The handle was relatively easy to form, as it starts square, then circular. After that it tapers all the way to the tip, which is tricky. The blade has to be judged by eye and touch, it is very hard to measure anything. I couldn't hollow each side of the blade as I don't have a round bottomed plane, but I think it looks quite good without the hollow.

The really tricky part will be making a second oar to match.

9 October 2014

New oars

I have started making a new pair of oars for my dinghy. The ones I have are too short and really not very good. I have got plans from Peter Culler's book on boat building, and adjusted the lengths a bit to suit. For timber I just got a pack of four eight foot boards from B&Q. Each oar is a sandwich of three boards. Much, if not most, of the outer boards will be planed off in the shaping process. This first photo shows the first oar blank cut out, alongside one of my current oars and an uncut board.

I marked the outline from the plans onto one board and cut it out on my band saw. This was quite a rigmarole as I had to unscrew the saw from my work bench and screw it onto a workmate so that I could get enough space for the board lengths on to and off of the saw table. Once I had cut one blank I used that to mark out the other five. This was quite a slow process. I think my saw blade must be getting blunt.

Three blanks are sandwiched together with polyurethane glue. A really messy process, the glue squelched out all over the place. Keeping the blanks in line was quite tricky as the clamps were tightened. The two outer layers are a bit narrower than the central one, but this won't matter as they will be carved down to a tapered side and won't come anywhere near the edge of the finished blade, The outer layers are unlikely to come more than a third of the way down the finished blade. I am seriously thinking of buying a power plane, because there is an awful lot of wood to remove.

I marked the outline from the plans onto one board and cut it out on my band saw. This was quite a rigmarole as I had to unscrew the saw from my work bench and screw it onto a workmate so that I could get enough space for the board lengths on to and off of the saw table. Once I had cut one blank I used that to mark out the other five. This was quite a slow process. I think my saw blade must be getting blunt.

Three blanks are sandwiched together with polyurethane glue. A really messy process, the glue squelched out all over the place. Keeping the blanks in line was quite tricky as the clamps were tightened. The two outer layers are a bit narrower than the central one, but this won't matter as they will be carved down to a tapered side and won't come anywhere near the edge of the finished blade, The outer layers are unlikely to come more than a third of the way down the finished blade. I am seriously thinking of buying a power plane, because there is an awful lot of wood to remove.

7 October 2014

First coat of paint on the patched deck

I am very pleased with the outcome of the deck repair. The first coat of paint is on and the repair is undetectable to touch. Still shows through visually, and it needs probably two more coats, but then it should be undetectable at all.

30 September 2014

Repairs and changes ongoing.

The basic repair to the cockpit deck is complete. I stuck in the infill panel with epoxy and then planed the patch down to flush with the deck. Some bits were a bit too low, so I spread on a layer of epoxy thickened with micro-balloons, which is supposed to give an easily sanded finish. I tried the technique of putting on the first layer with a notched spreader. The ridges are sanded down and then the remaining grooves filled in. It seemed incredibly hard, so I ended up planing off the ridges.

I then filled in the grooves with ordinary marine filler. This did sand down easily and although it looks a mess, it is completely smooth. When it is painted I have hopes that it really will be undetectable.

I have fitted turn buttons to the cabin floors and painted the boards with non-slip paint. I should now be able to lift the floor quickly at any time. I am not convinced by the paint as I think it may hold too much dirt, but I want to do away with the weight of floor finishes. I add too much to the boat and want to cut back next year.

I then filled in the grooves with ordinary marine filler. This did sand down easily and although it looks a mess, it is completely smooth. When it is painted I have hopes that it really will be undetectable.

I have fitted turn buttons to the cabin floors and painted the boards with non-slip paint. I should now be able to lift the floor quickly at any time. I am not convinced by the paint as I think it may hold too much dirt, but I want to do away with the weight of floor finishes. I add too much to the boat and want to cut back next year.

21 September 2014

Fitting deck glands

I came back form the Southampton Boat Show with bags of bits. One has proved far better than I anticipated. I wanted to fit a deck gland round the fuel pipe, so that I could block off the existing opening into the locker. This has let a lot of water in in the past, especially when I have several people on board and the stern is depressed. I assumed I would have to drill a new hole for the fuel pipe, and fill in the existing large hole. What I found was that the gland base covers the existing hole perfectly, so I can carry on using the same hole, but now it is waterproof. Not often that things just fit so neatly.

I am going to reroute the depth sounder cable to the opposite side of the boat. I can take it directly into the end of the quarter berth, through another deck gland, and then through trunking to the display unit. This means no unsealed holes into the cabin, which is how it is routed at present.

I am going to reroute the depth sounder cable to the opposite side of the boat. I can take it directly into the end of the quarter berth, through another deck gland, and then through trunking to the display unit. This means no unsealed holes into the cabin, which is how it is routed at present.

18 September 2014

Re-doing deck repair

I am re-doing the repair to the deck in the cockpit. It didn't look good and still flexed too much. When I had a closer look, the crack went right to the edge of the hatch opening. So I cut out a much larger area and started gluing substantial 12mm plywood beams under the edges. The deck around the hatch is very solid now, and when the infill goes in, it should be far better. Looks terrible at the moment.

16 September 2014

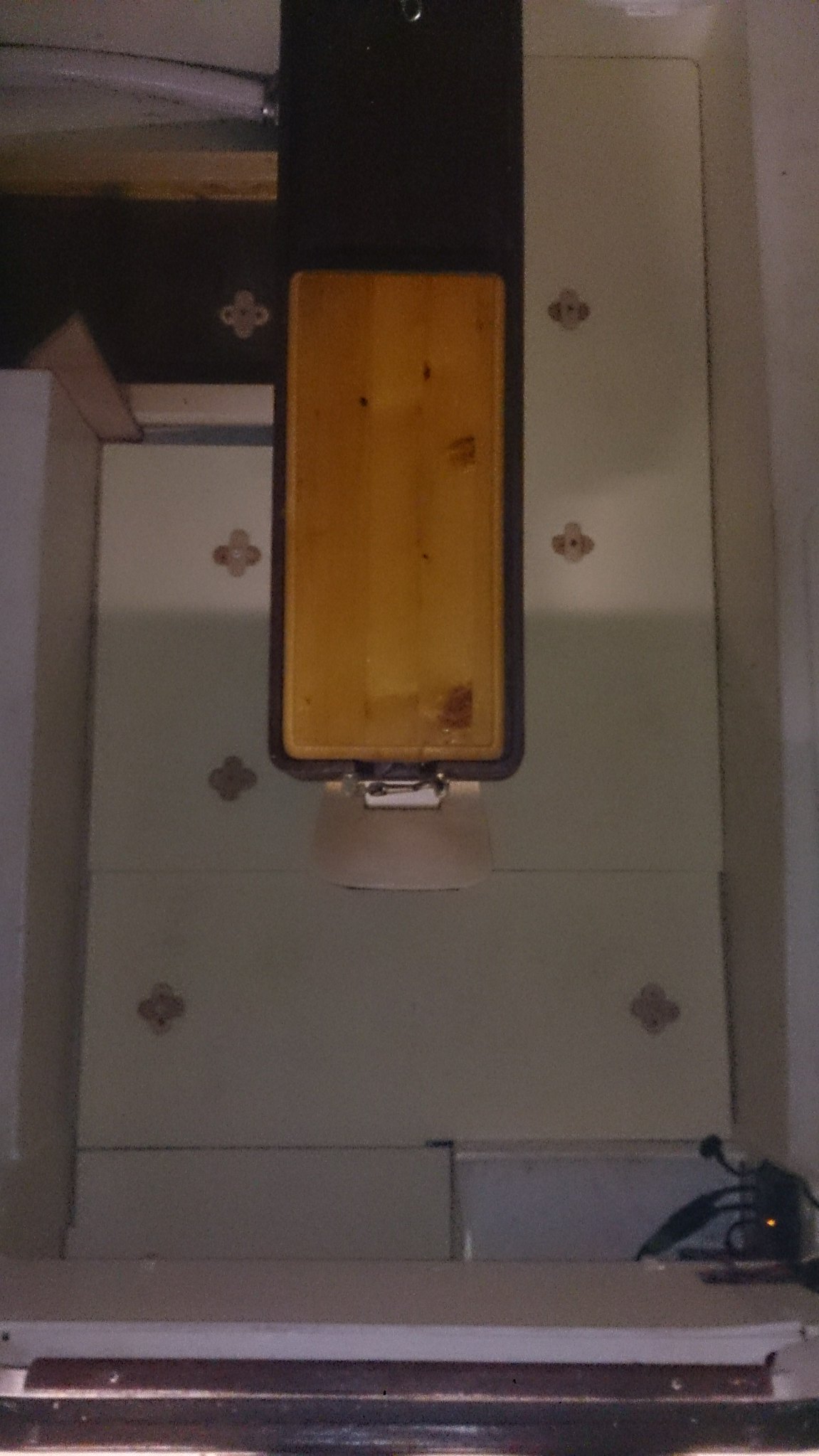

Outboard well blanking plate.

The blanking plate works well, and with four crew on board it is essential to fit it. Otherwise far too much water sloshes up into the cockpit and the self bailers in the sumps can't empty it quickly enough. Fitting the plate under way was very difficult. The space under the outboard is cramped and awkward to get at. The force of up welling water pushes the board out of the way until you can finally twist the locking bar in place. I have modified the set up.

First, I have enlarged the lips at front and back of the well to support the plate. and screwed on intermediate one just aft of the outboard leg in the down position. All in epoxy coated 6mm marine ply. These will need to be anti-fouled.

Then I sawed the plate into two parts, with a bevelled cut, so the edge of the smaller part can rest on the larger. The large part will be put in as before, and can be used when the outboard leg is down, which will be a bonus. It can also be fitted from either side. Full length it can only be fitted under the raised engine from the starboard side.

The short forward length will be hinged to the side of the opening with nylon hinges, so it can be flapped down when needed.

The forward part will be under water all the time as it is permanently in the well. I have considered various ways of hinging the larger part, but there just isn't room under the engine to do it in a simple to use way. But it will be much easier to fit in the shorter length. The small part will be held down with its own oak turn-buckle.

First, I have enlarged the lips at front and back of the well to support the plate. and screwed on intermediate one just aft of the outboard leg in the down position. All in epoxy coated 6mm marine ply. These will need to be anti-fouled.

Then I sawed the plate into two parts, with a bevelled cut, so the edge of the smaller part can rest on the larger. The large part will be put in as before, and can be used when the outboard leg is down, which will be a bonus. It can also be fitted from either side. Full length it can only be fitted under the raised engine from the starboard side.

The short forward length will be hinged to the side of the opening with nylon hinges, so it can be flapped down when needed.

The forward part will be under water all the time as it is permanently in the well. I have considered various ways of hinging the larger part, but there just isn't room under the engine to do it in a simple to use way. But it will be much easier to fit in the shorter length. The small part will be held down with its own oak turn-buckle.

12 September 2014

Winter work starts, and it is only September

I have started work on the cracked deck in the starboard side bench in the cockpit. The multi-tool cut out the triangular area perfectly. Very easy to plunge into the plywood and control the straight cut. The crack was bad, and surprising. The 6mm plywood looks quite robust, so why it cracked in this area I don't know. Not a highly stressed place, although I do stand on it when going onto the stern deck.

I have cut out two 6mm marine ply patches and coated them with epoxy. The larger goes under the hole and is epoxied top the underside of the deck. Held in place with string loops tightened with wedges.

When the glue is set, the second patch, which fits the hole, will be epoxied on top of the lower layer. This should be stronger than the original deck, if I make it properly. I will probably put a screw in at each corner, just for back up, as I don't trust my gluing all that much. Once all set there will be quite a bit of tidying up to do. (I am resealing all the hatches in the vain hope of making them fully watertight).

I have cut out two 6mm marine ply patches and coated them with epoxy. The larger goes under the hole and is epoxied top the underside of the deck. Held in place with string loops tightened with wedges.

When the glue is set, the second patch, which fits the hole, will be epoxied on top of the lower layer. This should be stronger than the original deck, if I make it properly. I will probably put a screw in at each corner, just for back up, as I don't trust my gluing all that much. Once all set there will be quite a bit of tidying up to do. (I am resealing all the hatches in the vain hope of making them fully watertight).

6 September 2014

Fantastic English Raid 66nm over a week

The English Raid was great fun. We got there a few days early as we had a flat booked at Mylor Harbour. That meant we could sail out amongst the Tall Ships, which were parading and then setting off for London. Absolutely wonderful to see and sail right in the midst of these huge ships and cutters.

The Raid was god fun, with light hearted racing around Carrick Roads, with picnics ashore and cream teas at the seaside Pandora Inn at Restronguet. The weather was fabulous. Sunny and breezy in the day and sunny and calm in the evening. Only slight disappointment was that we didn't go down to the Helford River, as the east wind would have made it hard for the smaller boats.

Brought Daisy G home. Decided it wasn't worth launching back at Poole for just a couple of weekends at the most. So the winter tinkering season is about to get underway.

The Raid was god fun, with light hearted racing around Carrick Roads, with picnics ashore and cream teas at the seaside Pandora Inn at Restronguet. The weather was fabulous. Sunny and breezy in the day and sunny and calm in the evening. Only slight disappointment was that we didn't go down to the Helford River, as the east wind would have made it hard for the smaller boats.

Brought Daisy G home. Decided it wasn't worth launching back at Poole for just a couple of weekends at the most. So the winter tinkering season is about to get underway.

27 August 2014

Off to the Raid

I went down to the marina today to pick up Daisy G and take her home and then down to Cornwall. Expected to be a while getting her in, but found that they had brought her ashore, pressure washed her and she was waiting on a stand. 10 minutes later she was on the trailer and we were on our way home. Don't plan to bring her back to Poole this season, it will hardly be worth it.

26 August 2014

Getting ready for hauling out. 7 nm

I will be getting Daisy G out this week to take to the English Raid in Falmouth next week. I sailed over to Redhorn Quay and used the calm weather to lower the masts and pump her out. I used the little Rule clone pump I bought at a boat jumble last February and it was fantastic. 10 minutes to pump both tanks dry. Far quicker than the manual pump, and I have never got the stern tank pumped dry before. I don't know how much it has drained the battery, but not to much in 10 minutes.

I have fitted a device to the battery to check the charge. I forget what it is called, but it flashes green when charged, orange when getting low and red when needing recharging. I think it works. When I have everything one, it was flashing orange. When I turned them off and the sun was shining, it flashed green after just a short while. So hopefully it is doing something useful and not draining the battery by itself.

I have fitted a device to the battery to check the charge. I forget what it is called, but it flashes green when charged, orange when getting low and red when needing recharging. I think it works. When I have everything one, it was flashing orange. When I turned them off and the sun was shining, it flashed green after just a short while. So hopefully it is doing something useful and not draining the battery by itself.

21 August 2014

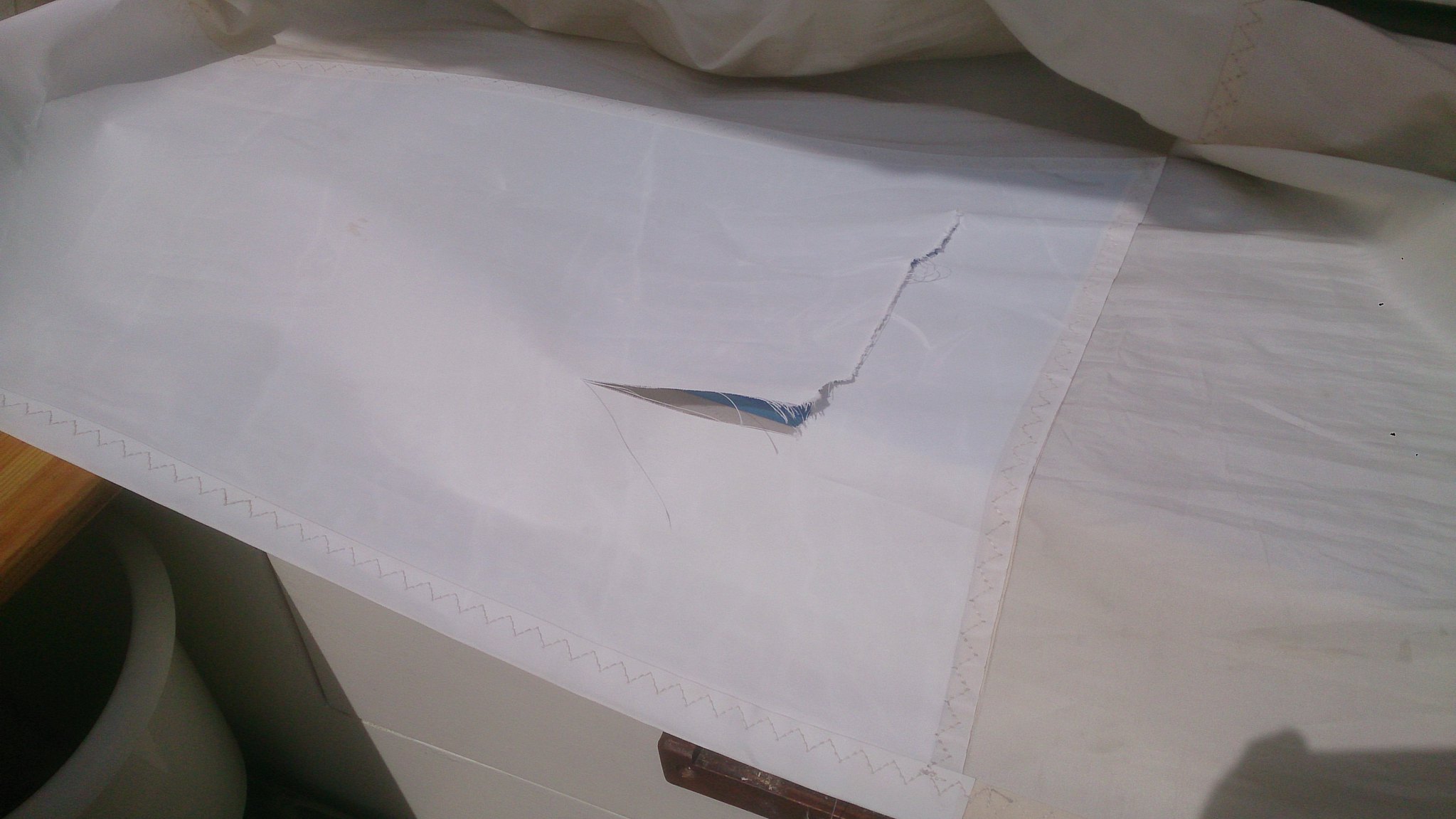

Getting ready for deck repairs

The cockpit bench is cracking near the stern, where I stand on it getting onto or off the stern ladder. I think the plywood is probably a bit too thin for its job here. I have marked the limit of each branch of the crack with a dot and marked out a triangle which covers the whole area I want to replace. I can't do any work directly on it until I get her home for the winter, but I have started preparing for the repair

I will cut out the cracked area with my Bosch multitool. Just to practice, I have cut out a 6mm ply patch from a larger sheet using the multitool and it works brilliantly. Far neater and quicker than a jigsaw, which requires drilling holes for the blade to plunge through. The multitool blade just shakes its way through in a couple of minutes.

Then I cut out a larger patch, which will go under the hole in the deck, when that is bonded in, the finishing patch "should" just drop into place. Then a bit of filling, sanding and painting and all should be better than new. I will glue in the under patch using the blind patching technique I used on my old fibreglass dinghy many years ago, which worked remarkably well. But I can t do it yet as It will take a few days (waiting for epoxy to cure mainly), and I need to get the plywood thoroughly dry. Rain has got in so the area is damp.

I will cut out the cracked area with my Bosch multitool. Just to practice, I have cut out a 6mm ply patch from a larger sheet using the multitool and it works brilliantly. Far neater and quicker than a jigsaw, which requires drilling holes for the blade to plunge through. The multitool blade just shakes its way through in a couple of minutes.

Then I cut out a larger patch, which will go under the hole in the deck, when that is bonded in, the finishing patch "should" just drop into place. Then a bit of filling, sanding and painting and all should be better than new. I will glue in the under patch using the blind patching technique I used on my old fibreglass dinghy many years ago, which worked remarkably well. But I can t do it yet as It will take a few days (waiting for epoxy to cure mainly), and I need to get the plywood thoroughly dry. Rain has got in so the area is damp.

18 August 2014

Maintenance day

Just down to Daisy G for the day to do some work on her. No sailing, just motored in to the pontoon. It was very windy in any case, up to F6 forecast. I have got my sail back from Concept sails. They just replaced the panel I had ripped, so good as new. Very good service, sail fixed and back on boat in under a week for £40.

I fixed a GRP tent hoop across the cockpit to brace the new sprayhood extension and this works well. Holds it up nicely and will stop rain pooling on it. I didn't even need to cut it to size, it just fitted. The ends are slotted into drilled oak blocks that I screwed to the outside of the coamings. when not in use, the hoops breaks down into short lengths and is rolled up in the extension which is lashed under the boom gallows.

I fixed a GRP tent hoop across the cockpit to brace the new sprayhood extension and this works well. Holds it up nicely and will stop rain pooling on it. I didn't even need to cut it to size, it just fitted. The ends are slotted into drilled oak blocks that I screwed to the outside of the coamings. when not in use, the hoops breaks down into short lengths and is rolled up in the extension which is lashed under the boom gallows.

11 August 2014

Wet and windy sailing 13.6nm

The forecast was for sun and the odd shower. Showers don't normally last all afternoon and night... But I have got my new spray-hood extension, which got a thorough trial. It took some experimentation to get it to fit, and I think I will fit a tent hoop at mid point to hold it up a bit more tautly, but it really does make the cockpit fully usable during heavy rain.

It slides into the track on the boom gallows and I will store it there. Still needs a bit of practice at stowing it so that it does not foul the main sheet. Quay Sails of Poole made it for me.

I have screwed a length of three strand rope around the dinghy as a fender, and that seems to have worked well, although the screws are not as invisible as I had hoped. The moved rowlock positions work well.

Saturday morning was blowing F4-F5 and plenty more. Hurricane Bertha wasn't supposed to arrive until Sunday! I sailed off the anchorage double reefed and all seemed fine until the mizzen gybed over. It wasn't cleated yet and it blew in front of its mast. At that moment the main followed suit and gybed across into the mizzen, which I was desperately trying to push back, but too late. Nasty rip in the mizzen where the main boom went into it. The sail is now with Concept sails waiting to be stitched up. I sailed out into Studland Bay with just main and jib, which worked fine, but it was too windy for my liking. I turned back into the harbour and had lunch anchored in the lee of Brownsea

It slides into the track on the boom gallows and I will store it there. Still needs a bit of practice at stowing it so that it does not foul the main sheet. Quay Sails of Poole made it for me.

I have screwed a length of three strand rope around the dinghy as a fender, and that seems to have worked well, although the screws are not as invisible as I had hoped. The moved rowlock positions work well.

Saturday morning was blowing F4-F5 and plenty more. Hurricane Bertha wasn't supposed to arrive until Sunday! I sailed off the anchorage double reefed and all seemed fine until the mizzen gybed over. It wasn't cleated yet and it blew in front of its mast. At that moment the main followed suit and gybed across into the mizzen, which I was desperately trying to push back, but too late. Nasty rip in the mizzen where the main boom went into it. The sail is now with Concept sails waiting to be stitched up. I sailed out into Studland Bay with just main and jib, which worked fine, but it was too windy for my liking. I turned back into the harbour and had lunch anchored in the lee of Brownsea

1 August 2014

19nm sailing in the sunshine with a new dinghy

A couple of lovely days in and around Poole Harbour, with a surprising amount of wind, so some very good sailing. Took my new dinghy down and launched her. She floats, rows beautifully and tows well, although she does drag more than the inflatable did. Really nice to row, but I need new oars. The sectional ones I have are too short and too thin. I kept thinking they would crack.

I sailed round to Studland beach and tested how she coped with swamping. Not well. Even with the stern buoyancy tank she completely swamps. I did get into her, but all was basically under water. I may try to fix some more buoyancy under the main seat. The skeg wheel works very well on the slipway, but not so good on sand and soft mud. I managed a little sculling, but it is a technique I need to practice on still water. Too much swell onto Studland sands. She carried loads really well. I brought the inflatable dinghy back to shore in her, without problem. I need to move the main rowlocks further forward to fit my long legs, and I must fit a rope fender around her as she scratched Daisy G each time I scrambled aboard.

The second day I spent tacking and tacking around the harbour. Getting up to 6kts on a broad reach, even with the dinghy in tow. She is quite noisy at night, with every ripple banging into her flat bottom and reverberating around. But I got used to it. She slides on and off the roof single handed very easily, which I am pleased with. That was the very first consideration when I chose the design.

I sailed round to Studland beach and tested how she coped with swamping. Not well. Even with the stern buoyancy tank she completely swamps. I did get into her, but all was basically under water. I may try to fix some more buoyancy under the main seat. The skeg wheel works very well on the slipway, but not so good on sand and soft mud. I managed a little sculling, but it is a technique I need to practice on still water. Too much swell onto Studland sands. She carried loads really well. I brought the inflatable dinghy back to shore in her, without problem. I need to move the main rowlocks further forward to fit my long legs, and I must fit a rope fender around her as she scratched Daisy G each time I scrambled aboard.

The second day I spent tacking and tacking around the harbour. Getting up to 6kts on a broad reach, even with the dinghy in tow. She is quite noisy at night, with every ripple banging into her flat bottom and reverberating around. But I got used to it. She slides on and off the roof single handed very easily, which I am pleased with. That was the very first consideration when I chose the design.

29 July 2014

Dinghy finished, yet to be launched.

I have finished my new dinghy, "Nellie Grace" Very pleased with the boat, but my paint finish is awful. I just can't paint. runs and dribbles everywhere and I may as well not have bothered masking areas off with masking tape. I don't know why I am so bad at it. But at least I won't worry about scratching her.

She went onto the roof rack quite easily as I had hoped. sliding n form the back. I think she is heavier than designed, due to the fancy seats and the extra work on the skeg and keel. I hope to take her down to Poole soon to try her out as a tender.

She went onto the roof rack quite easily as I had hoped. sliding n form the back. I think she is heavier than designed, due to the fancy seats and the extra work on the skeg and keel. I hope to take her down to Poole soon to try her out as a tender.

23 July 2014

Dinghy progress

The interior is now largely complete and painted. I am waiting for some longer stainless steel screws to fit the rowlock blocks permanently. I have built up the stern transom to provide a name plate, an outboard position, sculling slots and crucially, a sacrificial edge that I can stand the boat on as I heave it up on a roof rack (haven.t actually tried that yet, so hope it works.

Next I need to turn her over and smooth and paint the outside. Then she should be done, although I need to get some decent oars and then figure out how to secure them inside the dinghy when towing.

Not quite sure why I chose grey, but I am pleased with the colour scheme. Looks sort of dour and professional, unlike the quality of the finish. I was very pleased that the outboard started and ran very easily. It hasn't been used for over a year and I thought it would be fully gummed up with the old fuel in it. The Honda has a centrifugal clutch, which means it engages as you accelerate. Simple, but it makes tricky manoeuvres even trickier, especially when coupled with a lack of reverse...

Next I need to turn her over and smooth and paint the outside. Then she should be done, although I need to get some decent oars and then figure out how to secure them inside the dinghy when towing.

Not quite sure why I chose grey, but I am pleased with the colour scheme. Looks sort of dour and professional, unlike the quality of the finish. I was very pleased that the outboard started and ran very easily. It hasn't been used for over a year and I thought it would be fully gummed up with the old fuel in it. The Honda has a centrifugal clutch, which means it engages as you accelerate. Simple, but it makes tricky manoeuvres even trickier, especially when coupled with a lack of reverse...

Subscribe to:

Posts (Atom)